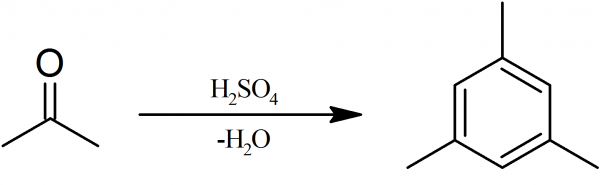

Preparation of Mesitylene

Mesitylene: 400 g of clean dry sand are placed in a 2ooo ml retort connected with a condenser. 250 g of acetone are added, and then a cooled mixture of 560 g of concentrated sulfuric acid and 150 g of water is run in, in a slow continuous stream, the retort being meantime cooled in cold water. After 24 hours standing, the mixture is slowly distilled, directly or in steam. When oily drops appear in the neck of the retort, the receiver is changed, and the distillate collected until only very small quantities of the oil appear.

The color of the liquid (if directly distilled) changes to deep brown, and finally to black, sulfur dioxide is evolved, and the mass froths up considerably. The upper yellowish layer of the distillate is separated from the lower aqueous layer, washed with sodium hydroxide and water, and dehydrated over calcium chloride.

It is then fractionated, the fraction 100-200° C being redistilled four times over thin slices of metallic sodium, when about two-thirds of it is obtained as pure mesitylene coming over at 161-166° C. Yield variable, about 25% theoretical (40 g). Colorless, strongly refracting liquid; b.p. 163° C; d= 0.8694 at 10° C.

Systematic organic chemistry, by W. M. Cumming, 57, 1937.