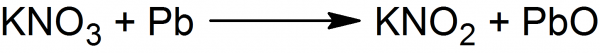

Preparation of Potassium Nitrite

Potassium nitrite is prepared (similarly to sodium nitrite) by heating potassium nitrate with elemental lead. Lead also could be replaced with metallic copper or zinc.

In an iron pan a mixture 100 g of potassium nitrate and 204 g of metallic lead is fused with proper stirring. Even at a low red heat the lead becomes for the most part oxidized and converted into a yellow powder – lead oxide (PbO).

To finish the reaction and oxidize completely remaining lead, the heat is increased to visible redness and maintained with stirring at that point for 30 minutes. Then the obtained mass is pulverized (while hot) and treated few times with boiling water.

The hot solution is filtered and hot filtrate is saturated with carbon dioxide by passing the gas through the solution for 5 minutes (but no longer!). Saturation with carbon dioxide forms lead carbonate, which is removed by filtration. The filtrate is treated with diluted nitric acid until the pH is neutral and cooled to room temperature.

The small amount of potassium nitrate is formed, which is filtered and filtrate is evaporated, preferably in vacuum, until the crystals of potassium nitrite appear. Finally, obtained crystals are filtered, washed with small amount of cold water, ethyl alcohol and dried in desiccator over anhydrous calcium chloride.

Laboratory manual of inorganic preparations, by H. T. Vulte, 52-53, 1895