Synthesis of Magnesium Bicarbonate

Magnesium Bicarbonate: The instant invention is based upon the discovery of a method for recovering extremely high purity magnesium carbonate from a magnesium hydroxide slurry. The magnesium hydroxide slurry can be produced in any conventional way, for example by adding lightly burned dolomite or lime, preferably the former, to sea water or the like to precipitate magnesium hydroxide, and then processing the precipitated hydroxide in a conventional way.

The slurry can also be produced by suspending in water burned magnesite, burned dolomite or other natural or processed materials which will form magnesium hydroxide that can be carbonated. Materials which form slurries containing less than about 90 percent of magnesium oxide, on a dry solids basis, are comparatively undesirable because they usually contain substantial amounts of water-soluble impurities which contaminate the final product and, in addition, are expensive because they require large quantities of high purity carbon dioxide.

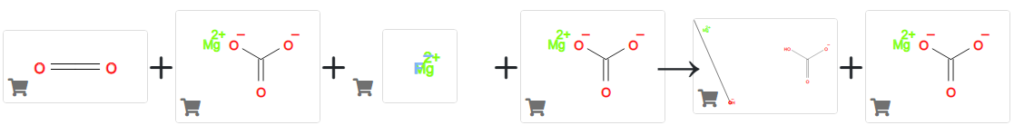

The method of the invention involves carbonating a magnesium hydroxide slurry to produce magnesium bicarbonate, and then continuing the carbonation to convert a part of the magnesium bicarbonate to a crystalline magnesium carbonate so that the slurry contains both dissolved magnesium bicarbonate and a crystalline magnesium carbonate precipitate.

Insoluble material is subsequently removed from the carbonated slurry by filtration, and the filtrate is decarbonated, for example by heating, vacuum, or both. Finally, hydrous magnesium carbonate of high purity, which is precipitated as a result of the decarbonation, is recovered, for example by filtration.

Literature source US04370307