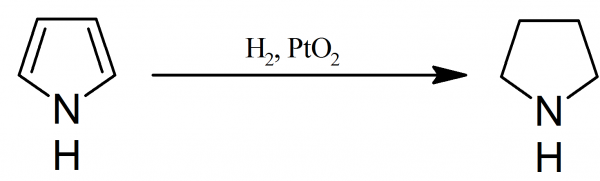

Preparation of Pyrrolidine

Pyrrolidine: 18 g of twice distilled from sodium pyrrole are dissolved in 60 ml of glacial acetic acid and hydrogenated with 0.5 g of platinum oxide. Absorption of hydrogen is throughout very slow and occasionally ceased completely, but the catalyst could be reactivated by shaking the reaction mixture with oxygen. Fresh portion platinum oxide (0.3 g) is added after 45 hours, and after 96-100 hours the theoretical amount of hydrogen has been absorbed.

After the platinum has settled, the dark solution was decanted, the acetic acid was neutralized with concentrated solution of sodium hydroxide under a reflux condenser in order to avoid loss of the volatile pyrrolidine, an excess of sodium hydroxide is added, and the mixture is distilled in steam until the distillate no longer reacted alkaline to litmus.

The ~1-liter of distillate is acidified with hydrochloric acid and evaporated to dryness. The dark, viscous residue is treated with 40% sodium hydroxide solution and extracted with ether, the ether extract is dried and the ether removed by evaporation. The crude pyrrolidine is purified by distillation collecting the fraction boiling at 85-88° C. The yield of pyrrolidine is 63% or 12 g.

L. H. Andrews; S. M. McElvain, J. Amer. Chem. Soc, 51, 889 (1929)

Pyrrolidine also could be hydrogenated pyrrole under pressure (M. De Jong and J. P. Wibaut, Rec Trav. Chim., 49, 237 (1930); L. C. Craig and R. M. Hixon, J. Amer. Chem. Soc, 52, 804 (1930))